Proper lubrication is the key to long life for your blowers. The Roots Universal RAI® (URAI) series utilizes grease on the drive end and oil on the gear end. The vast majority of remaining Roots products utilize oil on the gear and drive end.

Oil Viscosity

Oil viscosity is dependent on the expected ambient conditions surrounding the blower and driver.

The required viscosity is as follows:

Ambient Temperature above 90°F (32°C) use ISO Viscosity No. 320

Ambient Temperature 32°F to 90°F (0°C to 32°C) use ISO Viscosity No. 220

Ambient Temperature 0°F to 32°F (-18°C to 0°C) use ISO Viscosity No. 150

Ambient Temperature below 0°F (-18°C) use ISO Viscosity No. 100

Oil Lifespan and Change Intervals

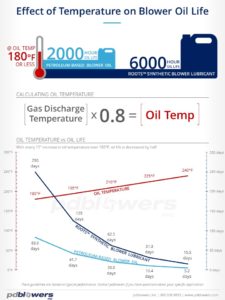

The oil should be changed after the initial 100 hours of operation. The ongoing oil change interval is based on the oil temperature, which is a product of the inlet air temperature, the vacuum level, the duration at a certain vacuum level, and consequently the discharge air temperature. As discharge temperature increases, there is a dramatic reduction in oil life.

The oil should be changed after the initial 100 hours of operation. The ongoing oil change interval is based on the oil temperature, which is a product of the inlet air temperature, the vacuum level, the duration at a certain vacuum level, and consequently the discharge air temperature. As discharge temperature increases, there is a dramatic reduction in oil life.

- Normal life expectancy of petroleum based oils is about 2000 hours with an oil temperature of about 180°F (82°C). As the oil temperature increases by increments of 15 to 18°F (8°C to 10°C), the life is reduced by half.

- Normal expectancy of ROOTS™ Synthetic Oil is about 4000 to 8000 hours with an oil temperature of about 180°F (82°C). As the oil temperature increases by increments of 15 to 18°F (8°C to 10°C), the life is reduced by half.

The oil temperature may be estimated by multiplying the discharge temperature of the air or gas stream by 0.8. As an example, if the discharge air temperature of the blower is 200°F, it is estimated that the oil temperature is 160°F.

Synthetic Oil vs Petroleum Based Products

Synthetic lubricants provide the longest life between oil change intervals and should be used wherever practical. ROOTS™ Synthetic Oil is superior in performance to petroleum based products. It has high oxidation stability, excellent corrosion protection, extremely high film strength and a low coefficient of friction. Typical oil change intervals are increased 2-3 times over petroleum based lubricants. Another important property is it is 100% compatible with petroleum based oils. Simply drain the oil in the blower and refill the reservoirs with ROOTS™ Synthetic Oil to maintain optimum performance.

Drive End Grease

For the Roots Universal RAI® blowers that utilize grease in the drive end, your unit may use a clay-based Shell Gadus grease or a synthetic Roots grease – click here to learn more about which grease to use. Note: Lithium based greases are not approved for use with ROOTS™ blowers.