In addition to end users, pdblowers often works with original equipment manufacturers (OEMs), providing equipment and packages that will be incorporated into other complex systems. For a recent project, we built four direct drive pressure packages to be used in industrial packing systems.

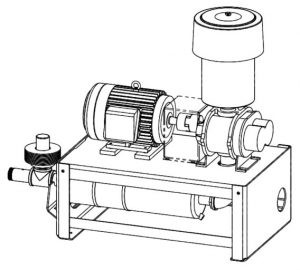

Package Equipment

Roots 45 URAI Positive Displacement Rotary Blower

VersaBase 034 with Integral Belt Guard and associated brackets for accessory mounting

Motor, 10 HP, TEFC, Premium Efficiency, 1800 RPM, 1.15 SF, 230/460 Volts, 3 Phase 60 Hz

Motor Slide Base, Double Adjusting

Drive, Direct-Coupled

Inlet Filter/Silencer, 2.5″, Paper element, CCS-2.5

Discharge Silencer, 2″, Chamber-Absorptive Type, Universal SD-2

Discharge Flex Connector, 2.5″, Silicone Impregnated Fiberglass

Relief Valve, Pressure, Weighted Type, 2″, Set at 9 PSI

Check Valve, 2″ MNPT, EPDM Seal

Pressure Gauge, 2.5″ Dia., 0-15 PSI, Liquid Filled, Snubber & Gauge Cock

Conditions

Conditions

– Inlet Volume: 138 ACFM (121 SCFM)

– Site Elevation: 175′

– Barometric Pressure: 14.6 PSIA

– Inlet Temperature: 100 °F

– Inlet Pressure Drop: 0.3 PSI

– Blower Inlet Pressure: 14.3 PSIA

– Discharge Pressure Drop: 0.2 PSI

– Discharge Pressure: 8.0 PSIG

– Blower Differential Pressure: 8.5 PSI

Performance

– Design Speed 1780 RPM (49% of maximum)

– Shaft Power: 8.3 BHP

– Discharge Temperature: 238 °F

– Differential Temperature: 138 °F (61 % of maximum)

– Discharge Volume: 108 ACFM

– Power at Relief Valve: 9.3 BHP

– Estimated Noise Level: 86 dBa at 3 feet