Product Line Details

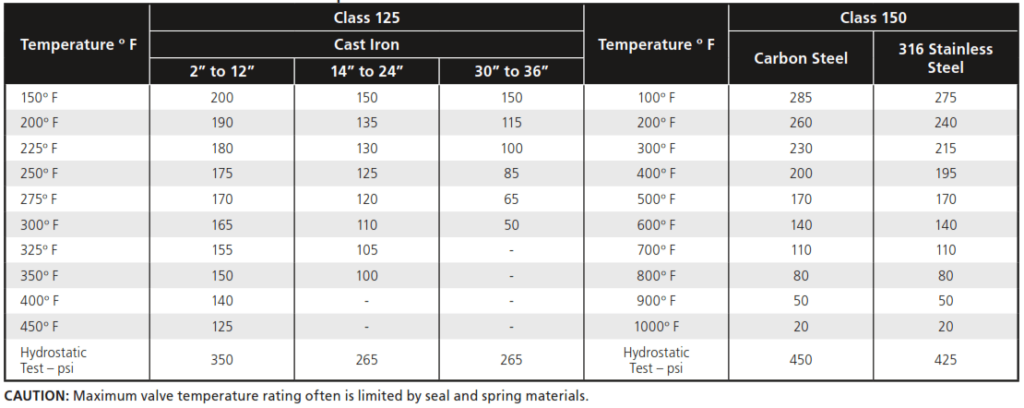

ASME Pressure – Temperature Rating

Maximum Non-Shock Pressure – psi

TECHNO Dual-plate, Metal-hinged Wafer-style Check Valves

- Compact wafer-style, one-piece design

- Center post fully supports the internal assembly without external pins or plugs

- No fugitive emissions to atmosphere is ensured due to its standard design, which eliminates through holes and pipe plugs in the body

- Maximum flow area reduces pressure loss

- Reduces installation space and time

VALVE PLATES

The dual-plate design produces increased strength with reduced opening and closing time.

CLAMP PLATES

Clamp plates offer additional strength to valve plates and allow seals to be changed easily.

SEALS

Specially designed flat, full-contact seals maintain positive shutoff at low working pressures. Unlike most other valves, these seals are replaced easily in the field.

SPRINGS

Torsion springs assist valve plate closure, preventing flow reversal. Consistent valve response ensures against slamming and water hammer.

SHAFT

The shaft features heavy-duty, corrosion-resistant construction.

SHAFT SUPPORTS

Shaft supports act as stops to prevent over-travel of valve plates. They are corrosion resistant with large shaft-bearing surfaces and are easily removable for internal assembly, maintenance or change.

THRUST WASHERS

Thrust washers reduce friction and wear of valve plate hinges.

Variety of Configurations

Techno offers a wide variety of wafer bodies in different styles and materials. These can be assembled with different disc, spring, and elastomer seal choices to make a valve that exactly fits your application. Contact pdblowers if you would like a quote on any of these options.

| BODY |

INTERNALS |

SPRING |

SEAT |

CLASS |

316 Stainless Steel

Cast Iron

Carbon Steel |

316 Stainless Steel

Bronze

Aluminum Bronze |

316 SS

INCONEL X-750

No Spring |

Buna N

EPDM

Silicone

Viton

Teflon |

ASME 125

ASME 150 |

Techno 5050 vs US Valve 31 Series

US Valve produces their own US Valve branded 31 series as well as the Techno 5050 series. While there were originally some minor differences between the two series, these are now the same valves even though they do have separate part numbers.

Originally the main functional difference between the two was the retainerless design of the Techno 5050 series, although the US Valve 31 valves are now available with a retainerless option as well. Retainerless valves feature a center post that fully supports the internal assembly without any external pins or plugs, so there are no holes and plugs in the body which could potentially allow fugitive emissions to atmosphere. If you have a gas application you may want to consider a retainerless valve.