Product Line Details

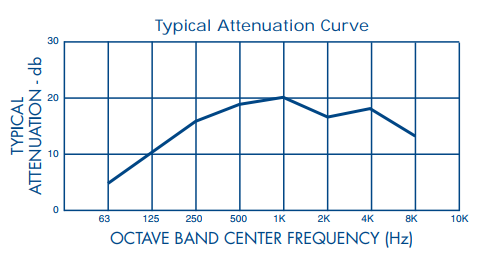

The Stoddard Series F64 Air Intake Filter and Filter Silencer is designed to mount directly on the inlet of an engine, blower or compressor. It will provide 16dB to 20dB noise reduction and the following efficiency:

- Paper element – 99% on 1 micron particles and larger

- Polyester felt element – 99% on 3 micron particles and larger

- Epoxy coated wire mesh – 90% on 20 micron particles and larger

To prevent the filter element collapsing, Stoddard recommends the differential pressure across the filter element should NOT exceed 15 inches of water column.

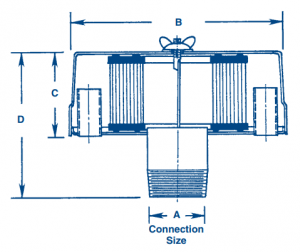

| Model |

A Connection Size |

B |

C |

D |

Rated CFM |

Weight |

Paper Element |

Felt Element |

Wire Element |

| F64-1 |

1″ NPT |

10 |

4 |

7 |

35 |

9 |

F8-108 |

F8-151 |

F8-129 |

| F64-1.5 |

1.5″ NPT |

10 |

4 |

7 |

80 |

9 |

F8-108 |

F8-151 |

F8-129 |

| F64-2 |

2″ NPT |

10 |

4 |

7 |

135 |

10 |

F8-108 |

F8-151 |

F8-129 |

| F64-2.5 |

2.5″ NPT |

10 |

4 |

7 |

180 |

10 |

F8-108 |

F8-151 |

F8-129 |

| F64-3 |

3″ NPT |

16 |

5 |

8 |

285 |

20 |

F8-109 |

F8-135 |

F8-130 |

| F64-4 |

4″ NPT |

16 |

5 |

8 |

520 |

20 |

F8-109 |

F8-135 |

F8-130 |

| F64-5 |

5″ NPT/FLG |

16 |

5 |

8 |

750 |

23 |

F8-109 |

F8-135 |

F8-130 |

| F64-6 |

6″ FLG |

20 |

5 |

8 |

1235 |

40 |

F8-110 |

F8-134 |

F8-131 |

| F64-8 |

8″ FLG |

20 |

10 |

13 |

2125 |

50 |

F8-111 |

F8-139 |

F8-132 |

| F64-10 |

10″ FLG |

26 |

15.5 |

20 |

3335 |

95 |

F8-137 |

F8-148 |

F8-142 |

| F64-12 |

12″ FLG |

26 |

15.5 |

20 |

4675 |

100 |

F8-137 |

F8-148 |

F8-142 |

| F64-14 |

14″ FLG |

26 |

15.5 |

20 |

5655 |

115 |

F8-137 |

F8-148 |

F8-142 |

Sizes 10″, 12″ and 14″ are FILTERS only

Click here to view all of our Stoddard Replacement Elements

Cleaning your Stoddard Filter Element

Turn off the air moving device prior to servicing. Remove the wing nut on the housing cover and then lift the cover off. Check the filter elements and then service using the instructions below. After cleaning, check inside the housing for loose articles before replacing the weatherhood and restarting the air moving device.

To extend the service life of a Stoddard paper filter, rap the element to dislodge accumulated dirt. Alternately, compressed air (75 PSIG max) can be directed through the element opposite to the direction of air flow to dislodge dirt. These paper filter elements will eventually need to be replaced.

For the polyester felt elements or polyurethane prefilters, wash in sink or large pan using water and any good washday type detergent and rinse clean. Squeeze out filter by pressing it against metal grid. Let stand and allow to dry completely. Felt and polyurethane elements will eventually need to be replaced.

Epoxy coated wire mesh elements should be soaked in hot water and detergent. After the element has completely dried, adhestive (light oil) can be applied at 1.5 to 2 oz.; allow excess to drain off prior to installing. These elements can be used indefinitely.