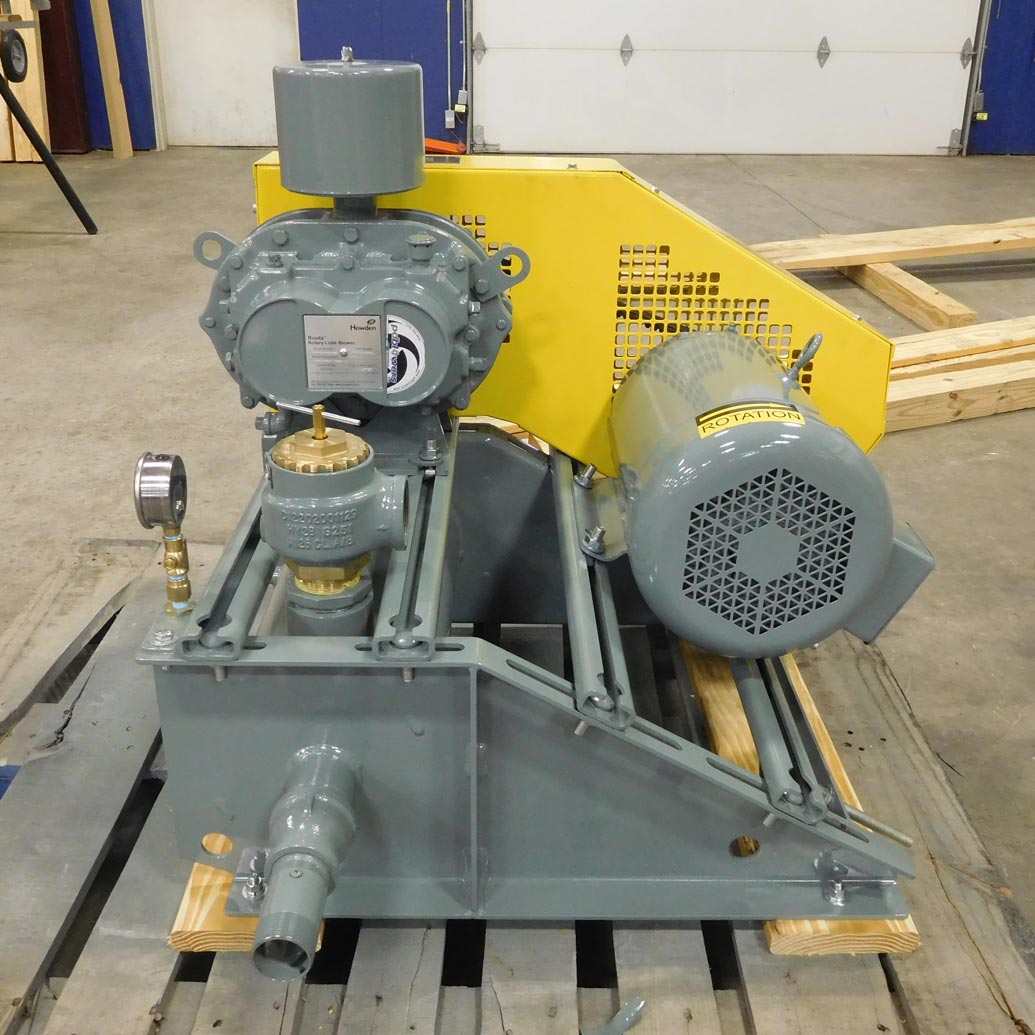

While most of our packages are built on pdblowers bases and skids, we are also happy to integrate other components to meet our customers’ specifications like this BBF-200 Solberg Base. This package is now installed at a wastewater treatment plant.

Package, Pressure, P1, 42 URAI-DSL, 7.5 HP Motor

Solberg Base BBF-200, CV

Roots 42 URAI DSL Positive Displacement Rotary Blower

Solberg BBF-200 Base with DL-200 Integral Belt Guard and associated brackets for accessory mounting

Motor, 7.5 HP, TEFC, Premium Efficiency, 1800 RPM, 1.15 SF, 230/460 Volts, 3 Phase, 60 Hz

Drive, V-Belt, minimum service factor of 1.4

Inlet Filter Silencer, 1-1/2″, Paper Element, Solberg FS-18P-150

Discharge Silencer, 2″, Built into base

Discharge Flex Connector, 2″, Silicone Impregnated Fiberglass

Relief Valve, Pressure, Kunkle 337, 2″, Set at 12 PSI

Check Valve, 2″ MNPT, EPDM Seal

Pressure Gauge, 2.5″ Dia.,0-15 PSIG, Liquid Filled, Snubber & Gauge Cock

Inlet Volume: 101 ACFM (87 SCFM)

Site Elevation: 500′

Barometric Pressure: 14.43 PSIA

Inlet Temperature: 100°F

Inlet Pressure Drop: 0.3 psi

Inlet Pressure: 14.13 PSIA

Discharge Pressure: 7 psig

Blower Differential Pressure: 7.5 psi

Design Speed 2346 RPM (65% of maximum)

Shaft Power: 4.9

Discharge Temperature: 213°F

Discharge Volume: 79 ACFM

Estimated Noise Level: 90 dBa at 3′ without noise enclosure