We developed our plate rolling capability in order to create the separators for our custom vacuum packages. Our application engineers now also use it to make round and conical shapes to build other systems. Our machine offers the best solution for bending plates between 59″ and 708″ in length, up to 80″ in width, and thickness up to 0.872″.

A Leading Standard in Position Technology

The SYNCHRO SERIES 4HEL 2122 machine, designed by Faccin USA, uses four rolls and a double pinch clamping operation. A cylindrical ferrule can be made in one pass, a highly productive method 3-4x faster than most other machines. NC and CNC systems control the clamping and driving of the plate during all phases of rolling.

We chose this system for our fabrication needs because it executes with extreme accuracy (0.008″ balancing accuracy) and efficiency. The electronic-hydraulic operation aligns the bending axis for highly precise bending geometry and kinematics.

Rolling Capacities & Process

Bending capacities depend on material yield strength. For example:

| Yield Strength | Length Range | Thickness Range |

|---|---|---|

| 36,000 PSI | 80" to 8" | 0.459" to 0.872" |

| 43,000 PSI | 80" to 8" | 0.427" to 0.811" |

| 65,000 PSI | 80" to 8" | 0.349" to 0.663" |

| 80,000 PSI | 80" to 8" | 0.312" to 0.593" |

The maximum inner diameter is 87″, with a minimum practical inner diameter of 9.53″ on lighter materials. Top roll size is 8.66″.

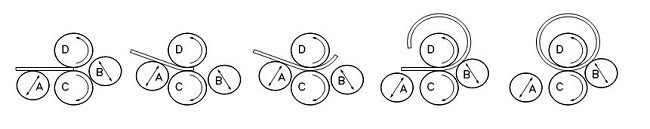

The rear roll (B) opposite feeding side helps to align the plate immediately on feeding. The top roll (A) and pinch roll (C) then clamp the plate securely throughout the process. After the first pre-bending, of the leading edge, side rolls and the central roll tilt to determine cone angle and immediately roll the plate to a desired diameter. The second pre-bending of the trailing edge follows. Traditional 3-roll bending machines require tilting the plate below feeding level for pre-bending the leading and trailing edges. Dual linear guides allow for horizontal feeding and more efficient material use. Electronic balancing synchronizes the moving rolls.

Custom Equipment

We’ll be happy to talk with you about how to implement your project through custom fabrication. Our application engineers will work from your initial plans to develop specific design criteria, then help you take your idea through to finished product. Contact us to learn more.