To meet the painting needs for our fabrication shop, we partnered with Global Finishing Solutions. The result is our temperature-controlled paint booth, allowing us to “bake” after painting and to maintain a high enough temperature to paint in the winter. We also manage oversized jobs with drive-through doors. Inside workspace dimensions are 20′ wide x 16′ high x 60′ long, allowing us to paint large objects that fit within those parameters. Among other components, we use it to paint custom containers that our shop builds from the ground-up. We use both conventional spray and airless technology to apply paint uniformly.

Eighteen-gauge galvanized steel sheets and structural steel hardware reinforce the booth’s construction. All functions are carefully calibrated and continuously monitored with a computerized system using industrial process controls. The booth operator oversees the job at an interface control station.

Painting to Specification

We paint every product fabricated at pdblowers, including blower packages. We meet all specifications and industry standards, including those set by the Society for Protective Coatings (SSPC) for surface prep and DFT (dry film thickness) standards set by the customer. For their superior performance, we use solvent-based primers and finish coat paints. We also work with specialty finishes like epoxies and polyurethane and offer powder finish as an outsourced option. These can be applied after blasting carbon steel or mild steel components.

We can create and apply custom paint colors. The defaults are “OSHA Yellow” for guards and “Equipment Gray,” using oil or water-based Sherwin Williams products. If your state regulations confine in-state painting to water-based, we can paint your component with oil-based paint and ship it to you, in accord with our state regulations.

Clean, Controlled Air Make Up

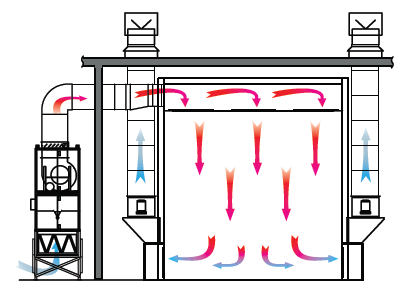

Our paint booth’s air make-up system provides process heat and a bake cycle for paint curing. The heating unit maintains the appropriate painting temperature, up to 140°F. A system for air replacement discharges air for an accelerated curing cycle. This system always uses outside, filtered air during the cure mode to ensure a clean environment.

Pressurizing the booth provides a cleaner environment; air entering the booth comes directly from the intake air source, bypassing potentially contaminated shop air. High efficiency filters remove dust and dirt at the ceiling intake vent. The system does not recirculate any exhausted air.

An auto-balancing system keeps air flow and pressure balanced during operation. Consistent air velocity is an important factor in achieving a quality paint job. The intake and exhaust filter layout allows even air velocity. Clean air is pulled vertically downward from the ceiling of the booth to the floor at an average velocity of approximately 50 fpm. A carefully designed exhaust system pulls air out of the enclosure through filter chambers running along the depth of the booth. This reduces overspray and creates the best finishes.

This system consists of a variable frequency drive that uses inputs from a differential pressure gauge and sensing probes to control an exhaust fan motor. Inputs monitor interior booth pressure and intake air then auto-balance exhaust fan RPM’s to an appropriate exhaust air volume. The result is a booth with optimized pressure and constant airflow.

Your Paint Job

Our painting capability is a turnkey service designed to meet each client’s needs: meeting industry standards and achieving complex projects to detailed specification. Contact us to plan your paint job.