Projects

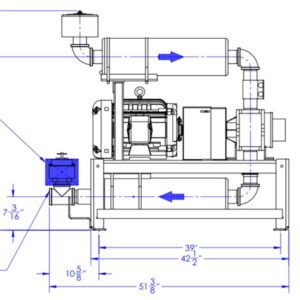

Positive displacement vacuum pumps are a staple in plastic resin conveying systems. These vacuum packages in our V5 configuration are designed to move LLDPE and FRPE polyethylene pellets through a conveying system. They feature inline filter silencers as well as a secondary discharge silencer for extra noise attenuation.

Hatcheries frequently use positive displacement vacuum pumps for conveying eggshells and other parts throughout their facilities. This vacuum package, in our V2 configuration, will be used in conjunction with an air/water separator.

Activated carbon injection (ACI) is an effective method to reduce toxic mercury emissions from coal fired power plants. These two enclosed, direct drive pressure packages will be used to inject the activated carbon at a large power plant in the United States that has won multiple awards for their commitment to reducing emissions through new technology.

This is our standard P2 pressure package featuring a Roots 56 URAI blower. It is on its way to South America where it will be used for wastewater treatment.

While all of our blower and vacuum pump packages are designed for easy access and maintenance, some installations may be limited by confined spaces. When space is a challenge, a compact design may be required to fit all of the necessary equipment within a small footprint. These packages were designed to replace the equipment in […]

Designed for a pneumatic conveying application, this pressure package features a large rotary blower that was repurposed and converted from gas service to air service for this new application.

Built on a skid for easy transportation to the site, this environmental system contains a blower package for pressure or vacuum service, an air/water separator, and heat exchanger, with a PLC control system. It was designed for 5″ Hg inlet vacuum and 4 PSI discharge.

Biodiesel is a clean-burning, renewable alternative to diesel fuel that is produced using different types of waste products collected from other industries, like used cooking oil from restaurants and factories. These oils and fats are turned into biodiesel through a chemical process known as transesterification. As a part of this production process, positive displacement blowers […]

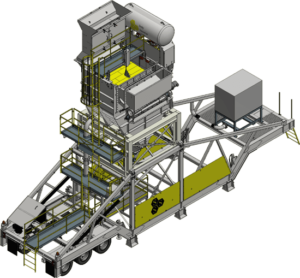

Pressure and vacuum systems are our specialty, but we do find it hard to pass up a fun challenge. One of our long-time customers knows our large material handling capabilities and comes to us for assistance with large special projects, like this self-erecting, transportable baum jig which we are currently fabricating.

Wood composite is a popular alternative to standard lumber for decking, fences, and other outdoor applications. These composite materials are made by combining wood flour with plastic resins and then forming them into boards by extrusion or injection molding. This customer of ours needed a pressure package to convey the wood flour from storage silos […]

Most of our projects begin with basic application specifications from our customers which our engineers use to size a custom blower package that will meet the requirements. In this case, our customer needed a pressure package to convey PET regrind through a 4″ line at 1500 lbs/hr. The total distance the material would travel is […]

Our customer is an environmental consulting firm who handles a range of projects including soil remediation, soil vapor extraction, air sparging, bioventing, mine dewatering, waste water handling, and more. This particular project is a vacuum system that will be used for soil vapor extraction.

This blower package is headed to an oyster hatchery where it will be used to provide aeration. The oystery is open to the public so it was important for this blower package to be contained in an enclosure to reduce the decibels of noise generated by the equipment. The solution we provided was a small […]

Our customer has created an innovative approach to wastewater aeration by pairing a shore-based power source with floating aeration units that are adaptable to a wide range of applications and climates. This blower package, along with the power and electrical components, will be housed in a weather proof enclosure on shore that feeds air out through flexible hose to the floating aerators.

pdblowers has assisted one of our long time customers with yet another large scale custom fabrication project, building many of the components for a wet jig system.

This 100HP pressure package featuring a 616 RAM blower is going to be installed at a state-of-the-art facility that recovers valuable zinc oxides from the industrial waste stream. More than a million tons of steel dust are generated by US steel mills using the electric arc furnace method to melt scrap steel. At this facility, […]

This 40HP 412 RAM pressure package is headed to a plant where kaolin is mined and processed for a wide range of applications including paints, plastics, paper, cement, ink, and insulation.

This customer was faced with an interesting challenge at an environmental cleanup site. A pump was needed to pull water at a variable rate from a deep well in a very remote location. Due to the unique circumstances of this project, modern remote communication technologies were not an option. Our team was able to help […]

At pdblowers we work with all types of customers, from end users and resellers to OEMs and other equipment integrators. This package was designed for a direct drive 4005 Tuthill blower and 15 HP motor which will be integrated by our customer once the package arrives at their facility.

At an industrial sewage lift station, a small pressure package was needed for aeration that could be contained in a lockable hinged enclosure. This lightweight aluminum clamshell enclosure is mounted over the package where it can easily be hinged open for maintenance and then locked in the closed position.

Is that a lawn tractor? Nope! It’s a vacuum pump package that will be integrated into a waste collection system for the textile industry

We have just completed a pressure package that will be part of a pilot program to capture carbon dioxide from power plant discharge. The 1012 RGS-J Roots blower package has many special features to extend its lifespan in a very harsh environment, such as electroless nickel plating on the blower and 316 SS accessories like […]

This enclosure was built to fit on top of an existing blower package in a plastic recycling plant. Our engineers worked with the customer to design an enclosure that would meet their sound dampening needs while fitting around existing equipment, electrical connections, and piping.

While most of our packages are built on pdblowers bases and skids, we are also happy to integrate other components to meet our customers’ specifications like this BBF-200 Solberg Base. This package is now installed at a wastewater treatment plant.

For one of our long-time soil remediation customers, we frequently assist them with equipment maintenance and retrofits. Soil remediation equipment may need refurbishment before moving from one cleanup site to another, or might be brought in to upgrade some of the components.

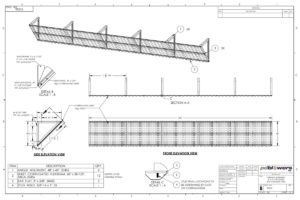

While pressure and vacuum systems are our primary focus, our production facility has all of the tools and expertise to fabricate large custom parts for our customers. In this project we built VLR Turning Vanes and a Fine Bubble Effluent Weir Box for a wastewater treatment facility. Our customer provided the specifications and initial drawing […]

This direct drive vacuum pump package was built for on-site soil remediation work. Since the customer frequently needs to relocate the package, they asked us to coat the skid in Rhinoguard to make it more durable. It also features a variable frequency drive (VFD) and control panel with wireless access so the equipment can be […]

In our 50,000 square foot manufacturing facility, large scale material handling is common. Gantries, hoists, and several large bridge cranes allow movement of even the largest fabricated components. So when one of our customers needed custom fabricated components for a large dewatering bucket wheel system, we were up for the challenge.

Our blower packages are used in a wide range of agricultural conveying applications. After final assembly, this pressure package will be integrated into a larger conveying system ultimately headed for a new peanut shelling plant.

These eight pressure packages will be integrated with turnkey systems that grind and shred waste wood, such as shipping pallets, into chips for removal and recycling.