For almost a century, Dresser meters have been used for billing of commercial and industrial gas loads. Accuracy, dependability, and low maintenance are of key importance in custody transfer measurement applications. The time-proven Dresser meter is the preferred rotary positive displacement gas meter in distribution, transmission and production segments for accurate measurement of gas from the well to the burner.

A complete line of rotary meter sizes is available to measure a wide range of gas volumes for the majority of commercial and industrial applications in custody transfer applications. Dresser meters are suitable for handling most types of clean, common gases at either constant or varying flow rates and pressure. They are ideal for applications throughout the meter’s operating range, from a few ounces to full maximum allowable operating pressure. Dresser meters are widely recognized for their highly accurate measurement capabilities at both the low and high ends of their rated capacity. The meter’s rangeability (ability to measure gas over a wide flow range within a specified accuracy) provides exceptional over-all measurement accuracy on a “day-after-day” basis.

The Dresser Meter Operating Principle

The Dresser meter is designed to measure the volume of gases and gas mixtures with a high degree of accuracy. The industry accepted rotary type positive displacement operating principle supports permanent, non-adjustable accuracy by using precision machined two-lobe impellers encased within a rigid measuring chamber.

Unlike other meter types, measurement accuracy is not affected by changes in gas specific gravity, pressure, or fluctuating flow. Dresser meters may be used from a few ounces to full capacity up of the meter’s maximum pressure rating with highly accurate measurement over a wide operating range. This equates to a lower total cost.

The condition of a Dresser rotary meter can be verified by performing a differential pressure test while the meter is still in service. This simple and cost-effective preventive maintenance procedure contributes to a significant reduction in the whole life cost of the meter.

Dresser Roots® Series B3 Line Mount Meters

Series B3 meters are designed to provide accurate gas measurement over widely fluctuating flow, pressure, and temperature conditions. For further versatility, the five smallest meter sizes (8C through 3M) have 2″ (50 mm) flanged connections, and a 6 3/4″ (171 mm) flange-to-flange dimension. If application requirements change, this unique, cost-effective feature allows a quick and easy meter exchange without the need to re-pipe the meter set. Other key features include:

- Capacity ratings from 800 CFH to 56,000 CFH (22,6 m³/h to 1,585 m³/h)

- Maximum operating pressure rating of 175 PSIG (12 Bar)

- Models 8C through 5M are available with a 200 PSIG (13,8 Bar) rating upon request

- Operating temperature range from -40ºF to +140ºF (-40ºC to +60ºC)

Dresser Roots® Series 3 Accessory Units

Designed for low maintenance and a long service life

- Interchangeability among Series B meter bodies of the same size

- Permanently lubricated for long life and virtually maintenance-free operation

- Modular design allows a quick-change to a different version at a lower overall cost

- Durable, weather resistant cover with improved sealing capability

- Versatile and configurable odometer masking

- Universal Instrument Drive (ID) assembly – one size fits all 8C-56M Series B Meters

- Quick and easy field installation of the low cost Solid State Pulser

- Available with factory pre-installed magnets for quick installation of the Solid State Pulser or Model 5 Prover Field Counter Pulser Module

Dresser Roots® Micro Corrector

This second generation Micro Corrector has the enhancements customers have been asking for. Using the proven IMC/W platform, features were added that make it the easiest corrector to use. Functions were added that improve low flow measurement, enhance data logging, and lower operations and maintenance costs while retaining the great features introduced in the original IMC/W.

The ROOTS Micro Corrector, model IMC/W2, functions as a compact integral component of the rotary meter, rather than being an adaptation of a product that cannot take full advantage of the integration of meter and corrector. It’s the only integral corrector rated for Division 1 hazardous locations.

Click to view pricing and more details about the Micro Corrector

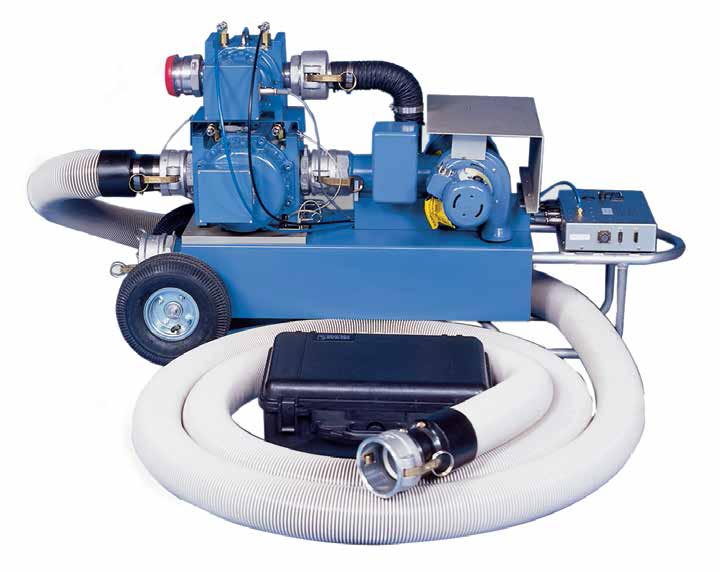

Dresser Model 5 Roots® Provers

Model 5 Transfer Provers feature an integrated computer controlled system for verification and testing of rotary, diaphragm, and turbine gas meters. After the field meter is connected to the Prover and the test sequence is selected, the remainder of the operation is “hands-off”. Test sequencing is automatically controlled by the software settings and the test results are displayed on the computer screen.

For ease of testing and recording, the Model 5 Prover system will:

- Store unlimited predetermined field meter test configurations

- Perform and display all calculations at the end of each test and allow for saving to disk

- Provide user-friendly menu prompts

- Allow easy access to extensive Help Files

The primary components for all Model 5 Prover systems include highly accurate Roots® master meters as measurement standards, a personal computer (not included) for operation of the system software, easy-to-use Windows®-based software, and a blower system to provide a stable air flow through the system vacuum.