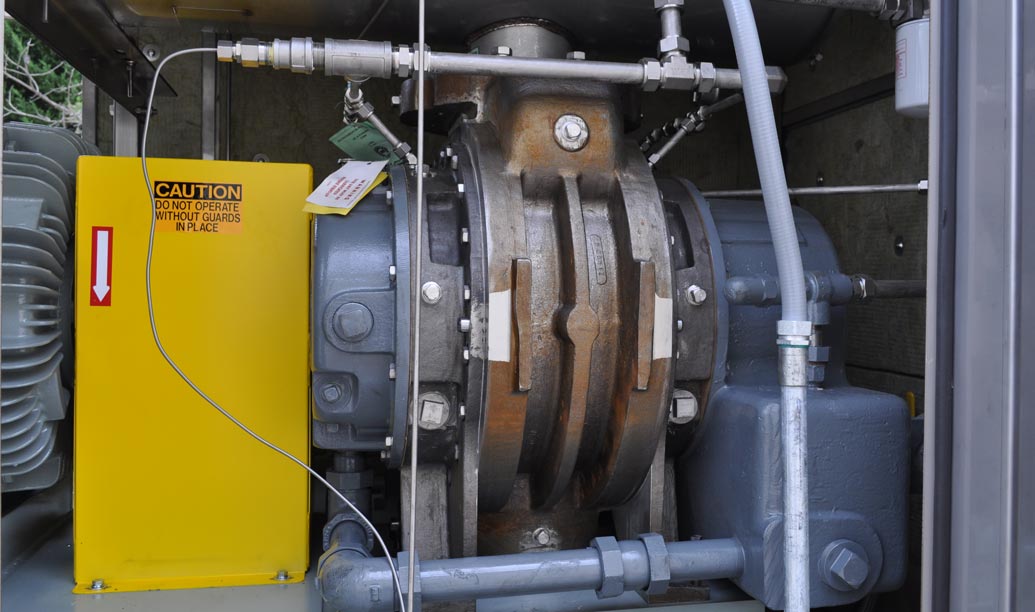

The Salton Sea Geothermal Field is a complex of geothermal power stations located along the shore of the Salton Sea in California. The environment can be extremely caustic at these plants, with high salinity in the nearby water and flammable, hazardous gas—hydrosulfuric acid (H2S)—in the air that will corrode away any equipment operating there. These two blower packages pull non-condensable gases up from the ground to pass through filtration and separation systems. The packages were designed to combat the effects of the H2S inside and outside the blower and extend the life of the equipment as much as possible.

Stainless Steel Blowers

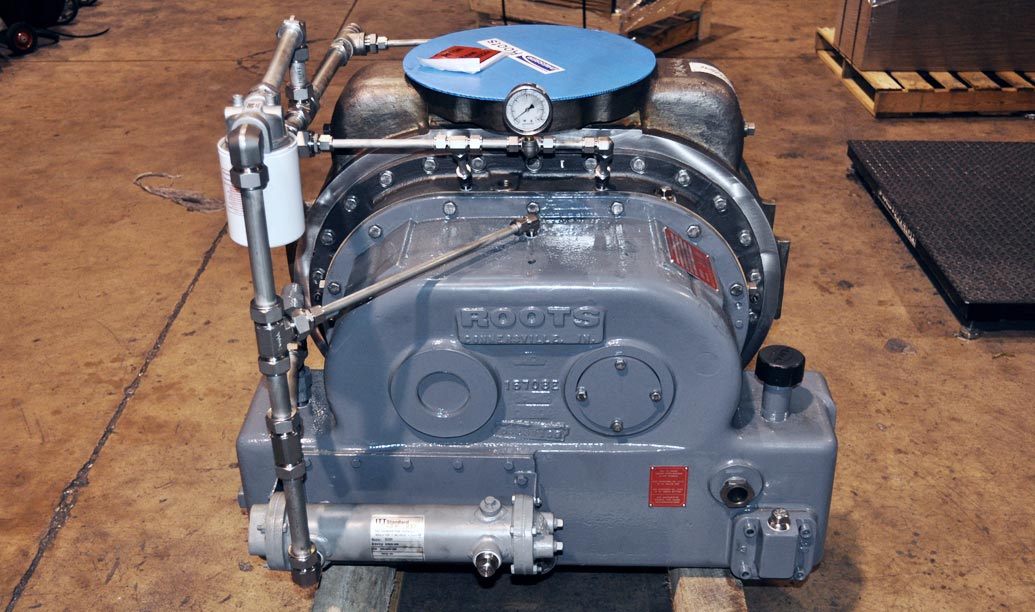

The blower in each package is a Roots Model 1009 RGS-J blower constructed with 316 SS wetted components including the cylinders, impellers, and headplates.

In addition, each blower features an auxiliary lube oil system and a base extension for the control panel and conduit.

Other Package Components

Each package also includes:

- Control panel with Allen Bradley VFD

- 316SS URDY-8 inlet silencer

- 316SS SURSY-6 discharge silencer

- 125 HP Motor 445T TEFC

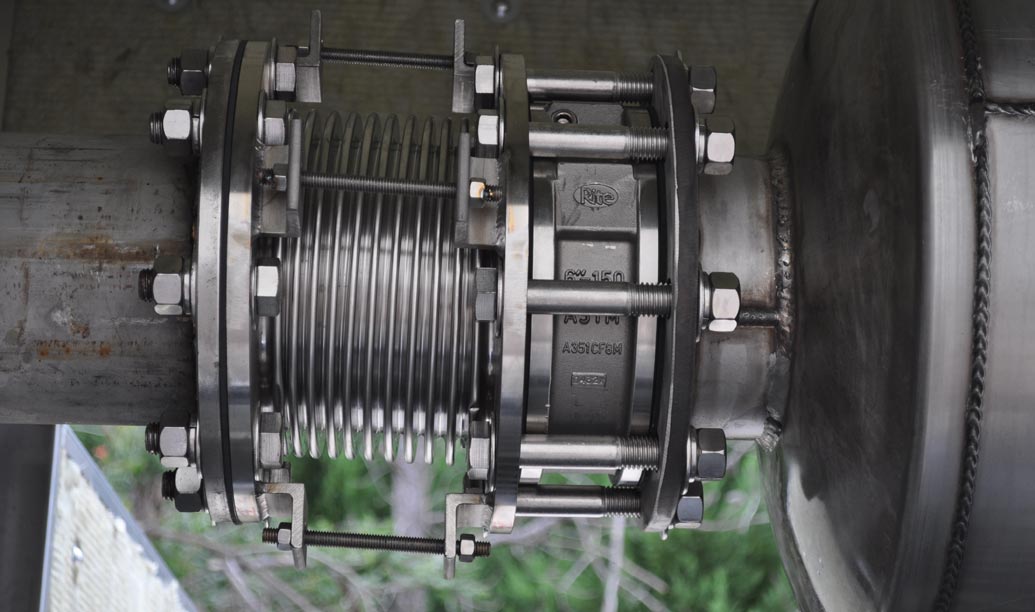

- 316 SS inlet and discharge expansion joints

- F8-132 stainless steel air filter

- 316 SS 6″ check valve

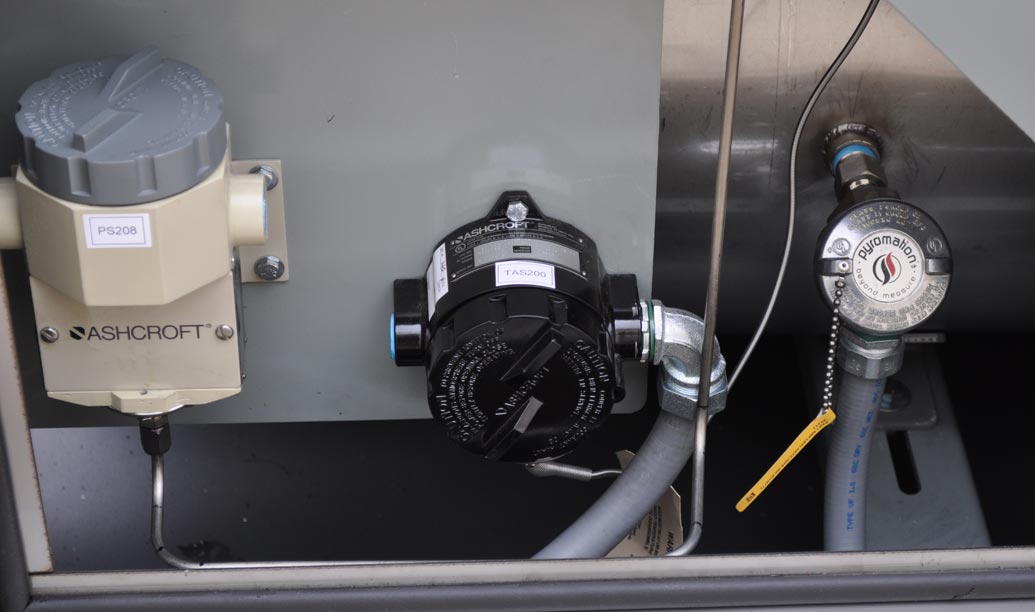

- Pressure gauge assembly

- 316 SS Thermowell temperature inlet and discharge gauges

- Thermowell RTD 100OHM

- NEMA 7 pressure and temperature switches

Stainless Steel Equipment Enclosures

Each blower package is housed in a custom stainless steel enclosure that helps protect the equipment from the outside environment. The enclosures were designed to accommodate the package dimensions and their expected heat load, with exhaust fans to vent warm air and keep the blowers from overheating. The enclosures are built onto custom fabricated sub-bases with anchors and lifting lugs for easy transport and feature hinged panels for easy maintenance. The control panel and VFD are housed within a separate Nema 4X SS enclosure positioned nearby.