If your application involves a corrosive process gas, you may find that your blowers quickly need to be replaced as the interior components of the blower are corroded over time by the gas. In these applications, special coatings or materials can be added to your blower to help protect your equipment and extend its lifespan.

Hard Chrome Plating

Armoloy / Gullite / Gullon / TDC

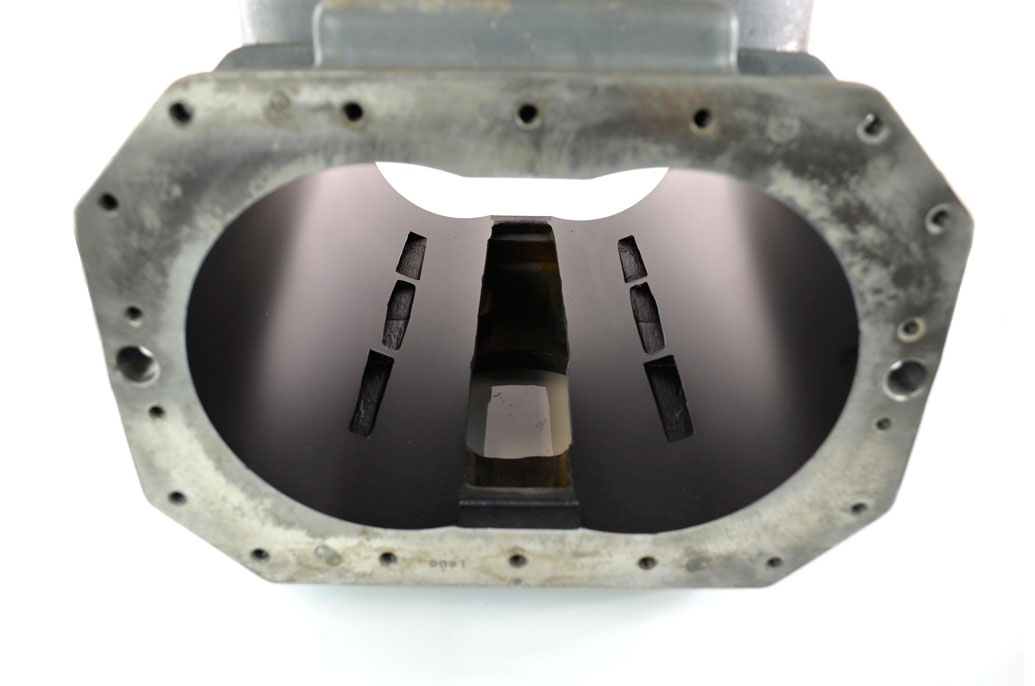

Thin dense chromium is an excellent choice for adding corrosion and wear resistance. The coating is applied only to the wetted parts of the blower, which would be the inside of the cylinder and headplates and the impellers.

With chrome such a thin layer of coating is applied that no machine modifications are needed, so this can be utilized on any blower model.

Electrolysis Nickel Plating

Available from the factory on large gas units, electrolysis nickel provides a hard coating that is corrosion, abrasion, and wear resistant.

A layer of nickel phosphorous alloy is chemically deposited for uniform thickness. Even though the coating is very thin (approximately 0.002″), it requires the blower parts be machined down to accommodate the additional thickness of the coating.

Stainless Steel Construction

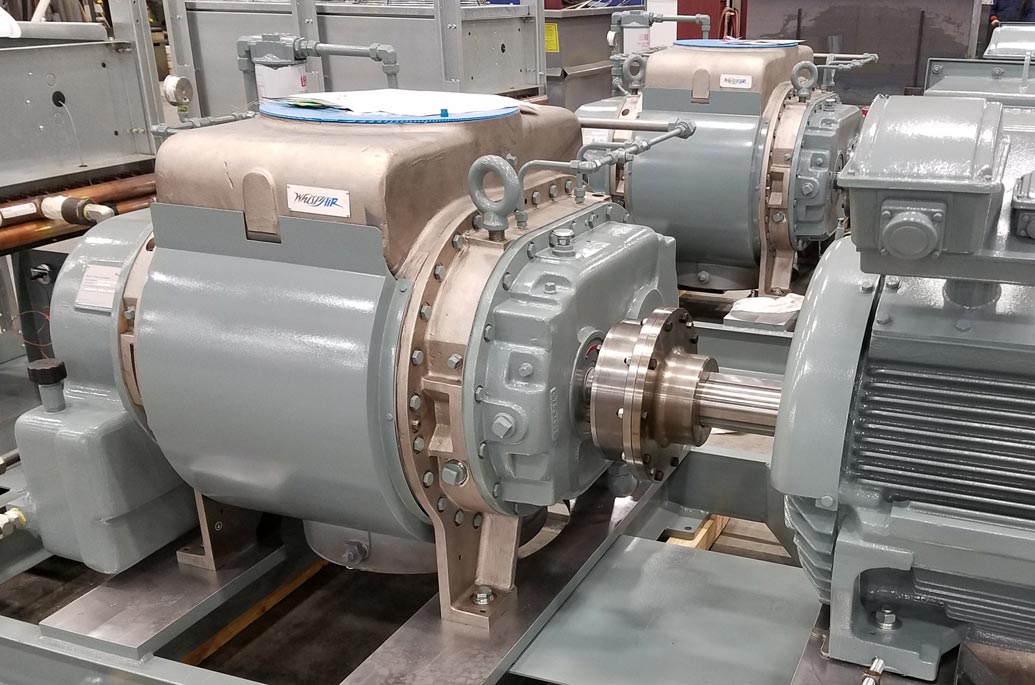

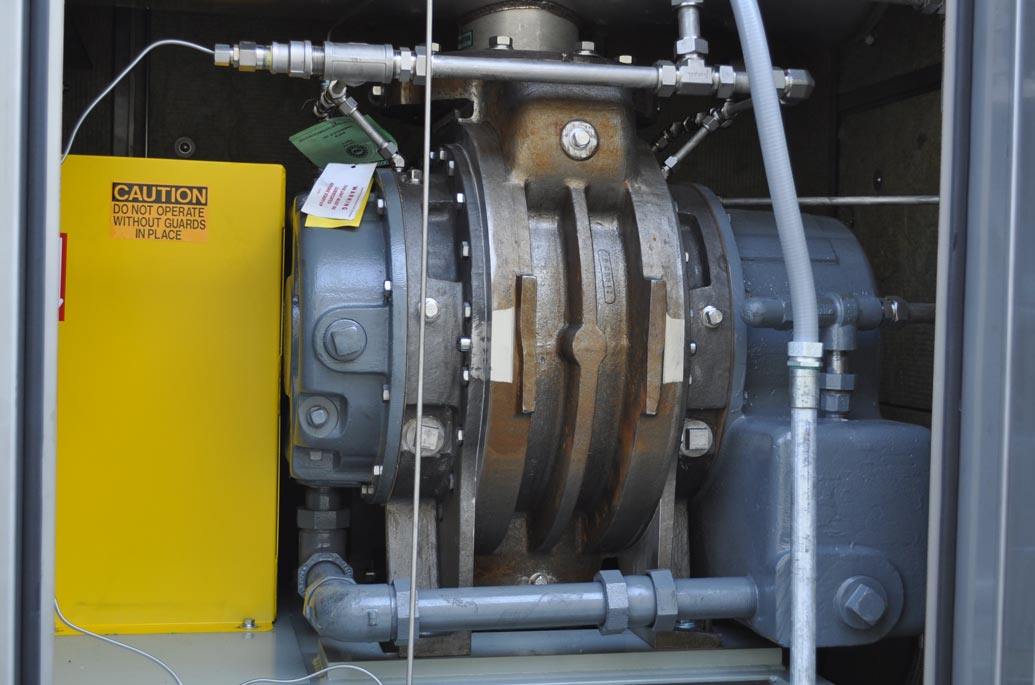

For extreme environments, blower components can also be constructed from stainless steel. These are produced by the factory for large rotary units.

The stainless steel blower pictured here was installed at a geothermal site where it pulls non-condensable gases out of the ground to run through various separators and filtration systems. Due to the highly corrosive environment both inside and outside the blower, stainless steel was used on the blower as well as the custom equipment enclosures that house the blower package.

If your blower is operating in a caustic environment where corrosion is a constant threat, it may be worth considering what options could help in your particular application. These solutions will not protect your blower indefinitely, but they can extend its lifespan. Any of these adders will increase the cost of the blower so it’s important to evaluate the replacement cost of your blowers against the additional service time you may get out of them with special modifiers.

Our team has decades of experience with pressure and vacuum systems operating in harsh environments and we can help you find the right solution for your unique application. Contact us to speak with our application engineers.